Securing Value

Meilink is gespecialiseerd in het ontwerpen en vervaardigen van bestendige verpakkingen en het deskundig verpakken, hightech reinigen en vervoeren van industriële kapitaalgoederen. In alle sectoren van de maakindustrie vertrouwen opdrachtgevers op ons om te zorgen dat hun goederen op tijd en in perfecte staat op de plek van bestemming komen. Wij voeren regie over alle stappen in de logistieke keten en waken over de waarde van elke levering. Dat is de betekenis van Securing Value.

Industriële verpakkingsoplossingen

Met industriële verpakkingsoplossingen zorgen wij dat uw apparatuur of installatie de juiste verpakking krijgt. Desgewenst geven wij al tijdens uw ontwerpfase advies vanuit het oogpunt van transport en logistiek van het product. Vervolgens doen wij de engineering van een verpakking die aan alle eisen voldoet. Met vijf productievestigingen produceren wij houten of kartonnen verpakkingen , beursverpakkingen, flight cases, vlonders, pallets en meer. High-end verpakkingen kunt u laten testen in ons ISTA gecertificeerd testcentrum

Hightech reinigen & verpakken

Veel producenten in de hightech industrie laten het hightech reinigen en verpakken van onderdelen door Meilink verzorgen. Dit gebeurt in onze cleanroom en kan zowel ultrasoon als handmatig gedaan worden. Hightech reinigen behoort tot onze kernactiviteiten, wij onderhouden daar de vereiste expertise en faciliteiten voor. Als klant kunt u hierover beschikken zonder het zelf allemaal in huis te hoeven hebben. Naast reinigen en verpakken onder beschermde omstandigheden leveren wij ook RGA-kwalificatie voor aantoonbaar deeltjesvrije schone onderdelen.

Logistieke diensten

Onze logistieke diensten zijn een verlengstuk van uw organisatie. Zo kunt u zich focussen op uw kernactiviteiten, terwijl wij zorgen voor transport en internationale expeditie, maar indien gewenst ook voor goederenontvangst, opslag, order picken en bundelen. Dat doen wij op basis van kennis van uw bedrijfsprocessen en van de benodigde logistieke diensten. Tot onze diensten behoort ook de effectieve inzet van herbruikbare verpakkingen.

Industriële verpakkingsoplossingen

Met industriële verpakkingsoplossingen zorgen wij dat uw apparatuur of installatie de juiste verpakking krijgt. Desgewenst geven wij al tijdens uw ontwerpfase advies vanuit het oogpunt van transport en logistiek van het product. Vervolgens doen wij de engineering van een verpakking die aan alle eisen voldoet. Met vijf productievestigingen produceren wij houten of kartonnen verpakkingen , beursverpakkingen, flight cases, vlonders, pallets en meer. High-end verpakkingen kunt u laten testen in ons ISTA gecertificeerd testcentrum

Hightech reinigen & verpakken

Veel producenten in de hightech industrie laten het hightech reinigen en verpakken van onderdelen door Meilink verzorgen. Dit gebeurt in onze cleanroom en kan zowel ultrasoon als handmatig gedaan worden. Hightech reinigen behoort tot onze kernactiviteiten, wij onderhouden daar de vereiste expertise en faciliteiten voor. Als klant kunt u hierover beschikken zonder het zelf allemaal in huis te hoeven hebben. Naast reinigen en verpakken onder beschermde omstandigheden leveren wij ook RGA-kwalificatie voor aantoonbaar deeltjesvrije schone onderdelen.

Logistieke diensten

Onze logistieke diensten zijn een verlengstuk van uw organisatie. Zo kunt u zich focussen op uw kernactiviteiten, terwijl wij zorgen voor transport en internationale expeditie, maar indien gewenst ook voor goederenontvangst, opslag, order picken en bundelen. Dat doen wij op basis van kennis van uw bedrijfsprocessen en van de benodigde logistieke diensten. Tot onze diensten behoort ook de effectieve inzet van herbruikbare verpakkingen.

Industriële verpakkingsoplossingen

Voor kwetsbare apparatuur en kapitale industriële machines leveren wij sterk maatwerk. Onze verpakking is méér dan een omhulsel. Ze maakt deel uit van een complex proces en moet perfect aansluiten op de keten van uw klant. Zo hoog mogelijke zekerheid tegen zo laag mogelijke kosten, daar zijn wij goed in. Inmiddels al ruim 70 jaar. Wij zorgen voor verpakkingsoplossingen van ontwerp en optimalisatie tot productie en high-end testen van unieke verpakkingen. Daarvoor werkt u van begin tot eind met één betrokken contactpersoon. Meer weten?

Hightech reinigen & verpakken

Productieomgevingen en gegarandeerd schone oplevering van componenten of onderdelen gaan niet samen. Daarom bieden wij diverse reinigingstechnieken in onze cleanrooms met uitgebreide faciliteiten. We reinigen manueel, maar ook ultrasoon. Het uitstoken van onderdelen in onze atmosferische uitstookoven is een extra reinigingsstap. Met onze RGA-containers meten wij de moleculaire reinheid van uw product, waarbij de grootte en hoeveelheid van nog aanwezige stofdeeltjes worden vastgesteld. Zodra het cleaning-proces is voltooid en geverifieerd, kunnen wij uw product assembleren, verpakken en gereedmaken voor verzending. Meer weten?

Logistieke diensten

Ieder zijn specialisme. Die van ons is logistiek van buitengewone, vaak unieke producten. Geen massaverzending van lage waarde, maar speciale verzending van hoge waarde. Daarmee kunt u zich als toeleverancier in de maakindustrie toeleggen op uw eigen specialisme. Wij zorgen voor regie via een betrokken contactpersoon en naadloze aansluiting op uw processen in de complete logistieke afhandeling. Dat maakt Meilink tot het verlengstuk van uw organisatie waarmee u deadlines van overeengekomen afspraken kunt halen, waar dan ook ter wereld. Meer weten?

Wij ontzorgen om de waarde van uw producten te borgen

- Uw leveringsbetrouwbaarheid

- Uiterste flexibiliteit

- De juiste oplossing in de gehele keten voor de laagste integrale ketenkosten

- Naadloze aansluiting op uw organisatie en processen

- Eén verkoper/adviseur als uw vaste aanspreekpunt

- Projectmanagement voor coördinatie en uitvoering

- Ontwerp tot en met integratie tot op plek van bestemming

Wij ontzorgen om de waarde van uw producten te borgen

- Uw leveringsbetrouwbaarheid

- Uiterste flexibiliteit

- De juiste oplossing in de gehele keten voor de laagste integrale ketenkosten

- Naadloze aansluiting op uw organisatie en processen

- Eén verkoper/adviseur als uw vaste aanspreekpunt

- Projectmanagement voor coördinatie en uitvoering

- Ontwerp tot en met integratie tot op plek van bestemming

Op tijd

Uw producten afgeleverd op de overeengekomen leverdatum

Onbeschadigd

Uw producten onbeschadigd op de plaats van bestemming

Flexibel

In alles flexibel, mee-ademend met uw projecten

Meilink in de ogen van

Peter Rikken – DGA

Bij ons kan eigenlijk alles. U kan het zo gek niet verzinnen, qua product of planning, wij regelen het. Dat is een kracht, maar soms ook een valkuil omdat de impact groter is dan de klant vaak beseft. Het zit gewoon heel diep in onze mensen, die nuchtere toewijding en trots om te zorgen dat de klus geklaard wordt. Het is een soort DNA dat overal in zit: onze langetermijnrelaties, onze flexibele systemen, maar ook de cultuur die van generatie op generatie wordt meegegeven. Niet alleen bij mij, maar ook bij alle vakmensen die hier werken. In mijn ogen is dat echt mooi aan Meilink.

Meilink in de ogen van

Peter Rikken – DGA

Bij ons kan eigenlijk alles. U kan het zo gek niet verzinnen, qua product of planning, wij regelen het. Dat is een kracht, maar soms ook een valkuil omdat de impact groter is dan de klant vaak beseft. Het zit gewoon heel diep in onze mensen, die nuchtere toewijding en trots om te zorgen dat de klus geklaard wordt. Het is een soort DNA dat overal in zit: onze langetermijnrelaties, onze flexibele systemen, maar ook de cultuur die van generatie op generatie wordt meegegeven. Niet alleen bij mij, maar ook bij alle vakmensen die hier werken. In mijn ogen is dat echt mooi aan Meilink.

Lokaal vertegenwoordigd

Wij zijn een wereldwijde speler die gewoon bij u in de buurt zit. Met acht vestigingen in Nederland hebben wij omvangrijke expertise op allerlei terreinen in huis. Maar wij spreken uw taal als het gaat om projecten.

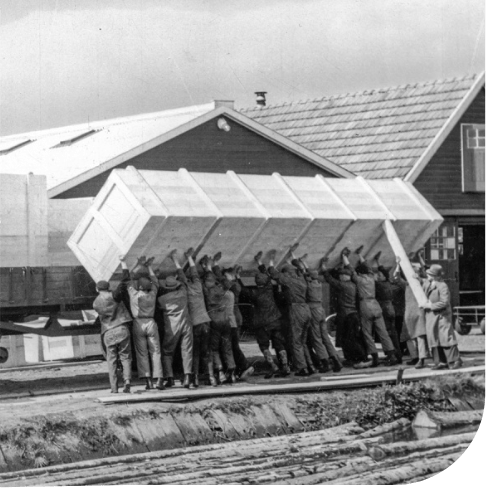

Geschiedenis

Meilink is het verhaal van drie families die achtereenvolgend vanaf 1874 tot aan de dag van vandaag met passie voor hun klanten zorgen. De huidige familie Rikken is, net als veel medewerkers, al meerdere generaties aan Meilink verbonden. Maatwerk is mensenwerk en dat blijft zo.

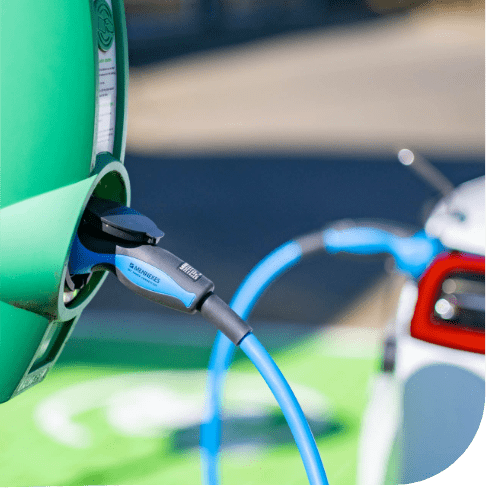

Duurzaamheid

Duurzaamheid over de relatie met onze werknemers, onze klanten, onze leveranciers en onze omgeving. Maar ook over energie, duurzame materialen en het tegengaan van verspilling. Wij geloven in een toekomst met hernieuwbare energie, zoals wind- en zonne-energie. Daarom zetten wij in op duurzame energie, hergebruik en het produceren voor zo min mogelijk afval.

Nieuws

Motoren op transport naar de woestijnrally in Abu Dhabi

Meilink ‘in the desert’ De klassieker in de woestijnrally’s, Abu Dhabi’s Desert Challenge, begint dit jaar op 25 februari. Om zeker te zijn dat de motorrijders dan ook van start kunnen, bestelde Impeco bij Meilink kisten voor het transport van de motoren. Wij leverden...

Als ondernemer mag je niet bang zijn om fouten te maken

Uit het artikel in Link Magazine nummer 1: De belangrijkste les die Peter Rikken leerde in zijn jaren bij Meilink is dat je meer goed moet doen dan dat je fout doet. ‘Als ondernemer mag je niet bang zijn om fouten te maken, want als je niets probeert, kom je nergens....

UNIEK JUBILEUM: 150 JAAR MEILINK

Op 24 januari 2024 bestaat ons mooie bedrijf maar liefst 150 jaar! In een tijd van grote technologische ontwikkelingen, snelle startups en vele prachtige bedrijven in de maakindustrie staat Want hoe bijzonder is het dat je als bedrijf door de uitdagingen van...